What is Marine Engine Diagnostics?

Marine Engine Diagnostics is the analysis of the engine’s built in computer system. This is done by connecting to the engine’s Electronic Control Module (ECM). The computers and software we use has an adapter unique to the engine manufacture to provide valuable information regarding the engines’ history. By connecting into the ECM we can learn valuable information regarding your potential purchase. By doing engine diagnostic scans this enables the surveyor to verify valuable information such as the actual engine hours, the RPM run history so we know how the engines have been operated during their life, current engine fault codes as well as historic fault codes. Engine diagnostics provides valuable information regarding the engine’s history to better enable our customers to make an informed decision before the purchase of the vessel. On inboard powered boats our sophisticated software has the ability to actually record the engines performance during the sea trial. This enables our surveys to verify the helm gauges accuracy and get exact details on the engine’s performance when sea trialing. Engine diagnostics is available as an additional option in conjunction with a marine survey on all gasoline inboard and most outboard engines providing the engines are ECM equipped.

Outboard Engine Diagnostics

Sun Coast Marine Surveying now offers engine diagnostics scans on all outboard and jet ski engines. The diagnostics software connects into the engines electronic control module and eneables our surveyors to veryify engine hours, RPM run history, fault codes and in some cases service history. This valuable information assists the buyer in making an informed decision when purchasing a vessel with outboards or a jet ski. This is an optional service offered only in conjunction with a marine survey on a vessel.

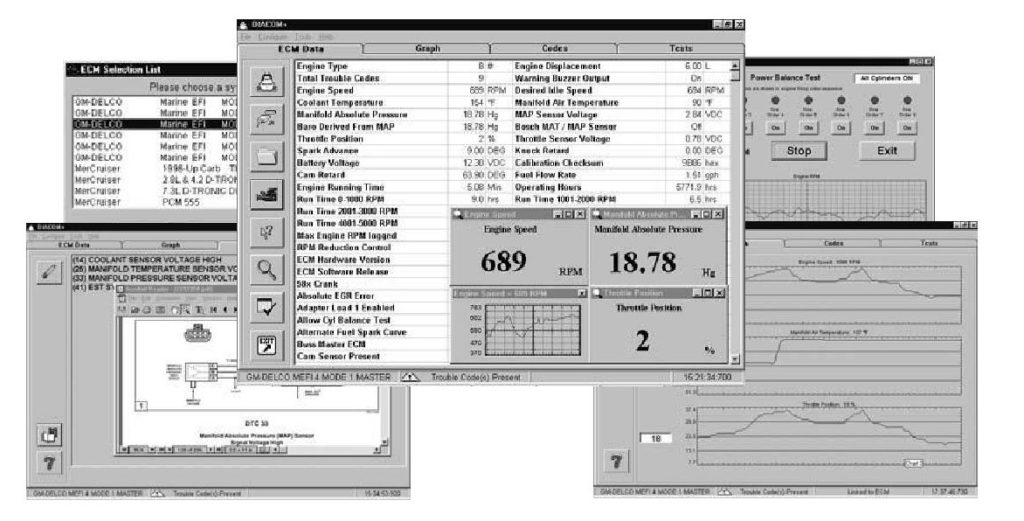

Outboard Engine Diagnostics Screen Shots

Diacom supports MerCruiser, Mercury Outboards, Volvo Penta, lndmar, Pleasurecraft Marine, Crusader, Ilmor, Marine Power, Kodiak, Flagship Marine, GM RamJet Engines and more…

The Diacom PC based diagnostic system gives you the power and flexibility you need to troubleshoot today’s advanced marine EFI systems. Diacom Marine supports the broadest range of engines in the industry providing superior coverage in a single diagnostic tool. Harness the power of your Windows based notebook or netbook PC to diagnose EFI system problems quickly and accurately.

The Diacom PC based diagnostic system gives you the power and flexibility you need to troubleshoot today’s advanced marine EFI systems. Diacom Marine supports the broadest range of engines in the industry providing superior coverage in a single diagnostic tool. Harness the power of your Windows based notebook or netbook PC to diagnose EFI system problems quickly and accurately.

- Productivity equals profitability.

Leverage the computing strength of industry standard notebook PCs to diagnose EFI faults in less time. - Stay compatible and competitive.

Easily access CD based service information, exchange engine data over the Internet, free yourself from dedicated diagnostic tools and take advantage of the latest notebook PC technology.

PC Diagnostic Power

Diacom Marine is a powerful Windows based diagnostic tool that is revolutionizing marine engie servi ce. With advanced engine control systems now standard on nearly all gasoline inboard, sterndrive and outboard engines, you need a service tool that pinpoints problems quickly and accurately. Diacom unlocks the power of your notebook or netbook PC and provides state-of-the-art features that simply leave other diagnostic tools in it’s wake.

You Spoke, We Listened

We started with a blank screen and designed Diacom Marine from the ground up with your feedback and suggestions in mind. After all, who knows better than you when it comes to getting your job done? Over the past decade we’ve collected a wealth of knowledge from the marine service technicians and dealerships we support. This gave our engineers quite a wish list of features to consider. Thanks to your input, Diacom has been made more intuitive, more streamlined, and more discoverable, so you can complete all of your work in less time.

Internet Connectivity

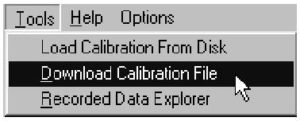

Chances are the Internet has already changed the way you interact with your customers and suppliers. Now it will change the way you troubleshoot. Diacom was designed to be Internet “aware” and provides features that allow the easy Diacom Kit Configurations exchange of data with other parties. Diacom can also convert engine data into formats easily read by other popular PC programs such as Microsoft Excel and Access.

Big Screen, Huge Advantage

Notebook screens have never been bigger and brighter. Diacom takes full advantage of your PC’s expansive display and shows you the “Big Picture” of what’s happening. Now you can spend less time pressing scanner buttons, scrolling through lists of parameters, and more time seeing what your EFI numbers mean. Diacom’s data display can be easily customized allowing you to view each EFI system type in a way that best suits your taste. Throw in features such as side-by-side twin engine displays, instant pop-up graphs, enlarged parameter windows, extensive data recording capabilities, report printing, and you’ll see why more marine technicians are choosing Diacom than ever before.

The Electronic Information Age

All of those years of searching through stacks of service manuals and technical bulletins are finally coming to a close. Most manufacturer’s now provide engine service information on CDs which can be easily searched and updated. Diacom has been designed to seamlessly access this information, displaying it effortlessly and accurately when you need it most. Simply click on any trouble code in Diacom’s display screen to launch the service information feature1.

Tests Made to Order

The marine industry’s ever increasing variety of EFI systems unfortunately means that tests designed for one type of engine control system probably won’t apply to other systems. Diacom’s adaptable “Tests” screen is designed to automatically configure itself for the EFI system under investigation. Using Windows ActiveX programming technology, this feature simplifies your work by displaying and delivering the unique set of tests that apply to the particular system you are troubleshooting.

Special Functions

As a factory authorized dealership you know the value of having the latest service technology at your fingertips. Working closely with marine engine manufacturers, we have incorporated specialized EFI system functions2 into Diacom Marine. Now factory authorized service facilities can use a single integrated diagnostic program to not only troubleshoot but also perform system upgrades and memory updates electronically in just minutes. ECM exchanges can now be minimized and in most cases entirely eliminated.

As a factory authorized dealership you know the value of having the latest service technology at your fingertips. Working closely with marine engine manufacturers, we have incorporated specialized EFI system functions2 into Diacom Marine. Now factory authorized service facilities can use a single integrated diagnostic program to not only troubleshoot but also perform system upgrades and memory updates electronically in just minutes. ECM exchanges can now be minimized and in most cases entirely eliminated.

For More Information

To obtain a comprehensive list of features and information about Diacom Marine as well as other Rinda Technologies products, please visit our website at www.rinda.com. Product specialists can also be reached in the USA and Canada by calling 773-736-6633.

Diacom Kit Configurations

94010 – Diacom Marine: includes Diacom

CD, USB cable, #94005 MEFI and

#94006 PCM-555 adapters.

94030 – Diacom Marine + CAN: includes

Diacom CD, USB cable, #94005 MEFI

and #94006 PCM-555 and 94029 CAN

network adapters.

System requirements

To use Diacom, you need:

- Notebook or Netbook PC with 1 Ghz or higher processor.

- Microsoft Windows 7, Windows Windows Vista, Windows XP (both 32bit and 64bit versions of Win 7 / Vista are supported)

- 512 MB of RAM minimum

- 150 MB or greater of available hard disk space.

- CD-ROM drive

- USB port.

- SVGA (800 x 600) or higher resolution display screen.

- Mouse, touchpad, or compatible pointing device.

Additional items or services required to use certain features:

- Internet connection for email and web related features.

- Appropriate document viewing utilities such as Adobe Acrobat and Microsoft Internet Explorer to view electronic service information.

- Diacom special functions require usage authorization and data files supplied by engine manufacturers.

1. Engine service manuals in electronic format must be obtained from the engine and /or vehicle manufacturers.

2. Usage restrictions apply based upon dealer type and status. Diacom special functions vary with EFI system type and engine manufacturer.

Please note all specifications are subject to change without notice. Photos and screen images shown may differ based upon product version or other factors. Information presented in this document is believed to be accurate. Responsibility for errors, omisstbof inform ation or results from the use of this information cannot be assumed by Rinda Technologies, Inc.